Autonomous Mining Truck

Autonomous Mining Truck

Conducting full testing and verification of all functions on the mining trucks, including control, perception, decision-making, localization, planning modules, etc., to enhance the rapid implementation and tuning of algorithms.

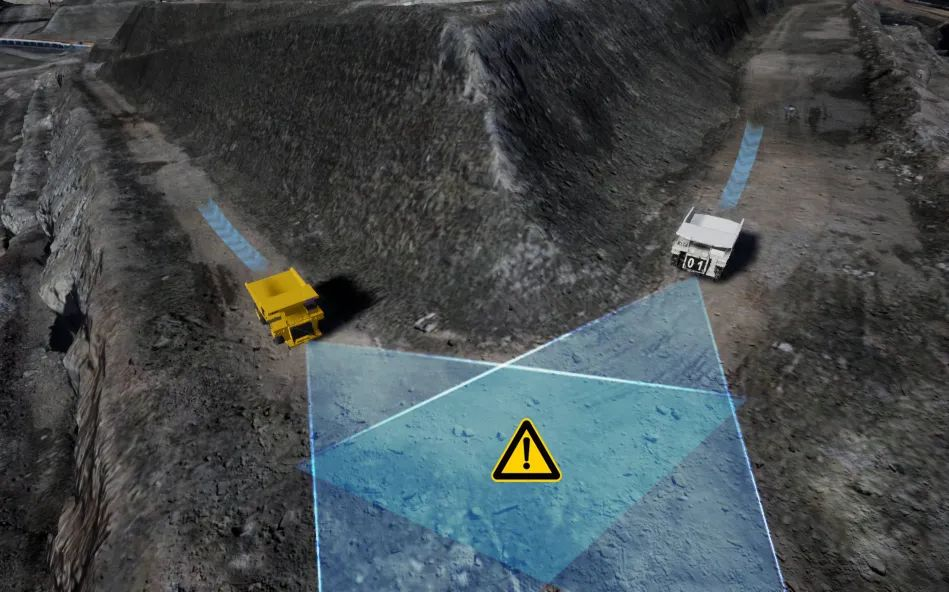

V2X Functional Verification

V2X Functional Verification

Conducting V2X and anti-collision joint function tests, including following and meeting function tests at intersections, structured roads, operational areas, etc.

Digital Twin Simulation

Digital Twin Simulation

Through the high-speed transmission performance of 5G networks, the system is able to synchronize the vehicles in the virtual environment with the real vehicles, realizing the digital twin achievements between real and virtual vehicles.

Fleet Operations Management

Fleet Operations Management

Conducting multi-vehicle scheduling management tests with the far exceeding number of vehicles for the testing site to find optimal scheduling strategies, reduce safety risks, and firmly promote project implementation.

Software & Hardware Performance

Software & Hardware Performance

Combining with the actual situation on sites, we build a 1:1 corresponding virtual environment, and conduct hardware and software testing on durability and reliability.

Cooperative Operations

Cooperative Operations

Real-time testing for cooperative operations betwwen excavators and trucks, including entry mechanism, loading mode, exit mechanism, security mechanism and etc..

Reduce 90% time on on-site commissioning

Speed up the algorithm iteration and convergence

Improve system development efficiency

Save on business expenses

Improve safety and reliability