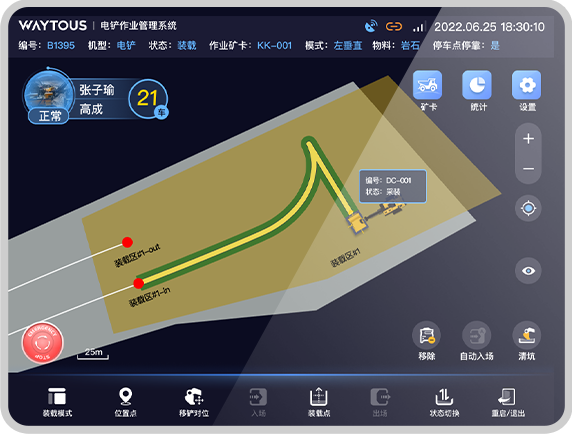

Real-time Status Monitoring

Real-time Status Monitoring

The function displays the location in maps and real-time operation status of mining, transportation, engineering and auxiliary equipment, and supports the whole process of collaborative operation and production.

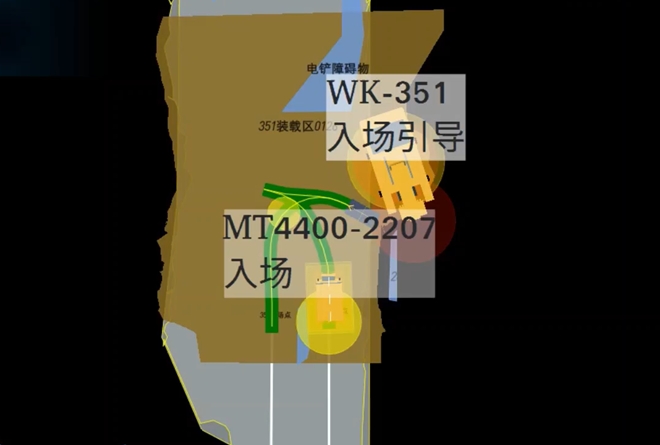

Vehicle Scheduling Collaboration

Vehicle Scheduling Collaboration

The system is equipped with a scheduling management module, which can receive scheduling instructions from the autonomous fleet management, and different types of collaborative equipment can complete the operation targets according to the specific tasks.

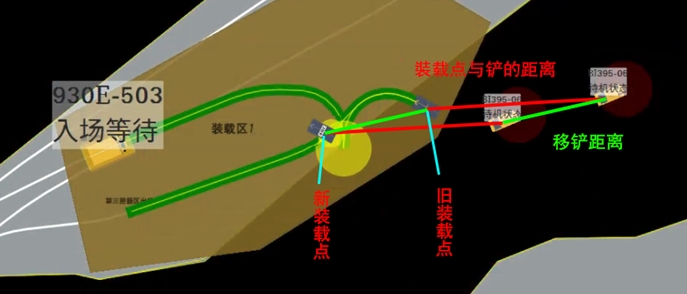

Collaborative Work Site Management

Collaborative Work Site Management

When a driver or the system points out desired location for the autonomous mining truck, such as exits, entrances, parking lots, etc., the cooperative loading management system could automatically plan and generate the entry and exit routes of the autonomous mining trucks to complete the collaborative tasks.

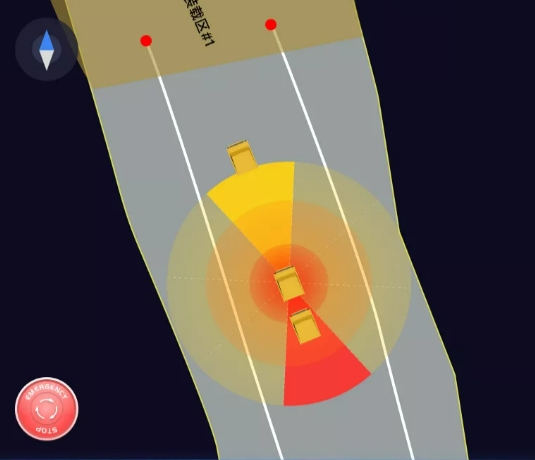

Vehicle Safety Control

Vehicle Safety Control

The system is equipped with safety anti-collision and emergency stop functions. The circle of the collaborative equipment is divided into warning, speed reduction and emergency stop circles, which will automatically warn, keep the speed slow and stop when the autonomous mining truck comes into contact with different circles of the collaborative equipment; at the same time, when the collaborative equipment finds that the autonomous mining truck is running abnormally in the unloading area, it can make the truck stop urgently through the emergency stop function to ensure the operation safety.

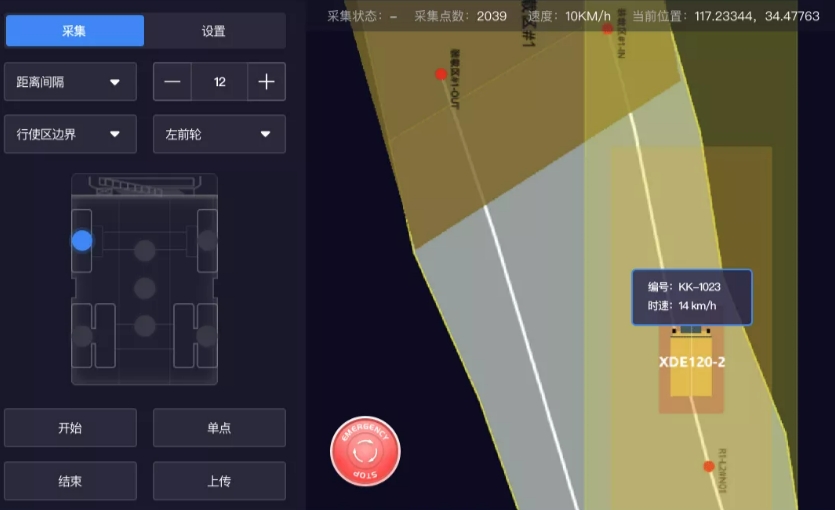

Map Acquisition at Operating Area

Map Acquisition at Operating Area

This function can carry out map acquisition of designated areas, such as loading area, unloading area, drivable area, etc., based on the vehicle location information obtained from the localization module, and it could elabroate the current acquisition status, the number of cites, latitude and longitude information of the platform during the map acquisition process. After the collection, the map will be automatically uploaded to the autonomous fleet management for storage, maintenance and update.

Accurate & Effective: technology supports the whole process of "Mining-Transporting-Dumping"

Stable & Reliable: ensuring the safety of the mining production as a powerful safeguard

Practical & Applicable: building the real smart mining system

Fast & Accurate: producing operation data collection and real-time traceability